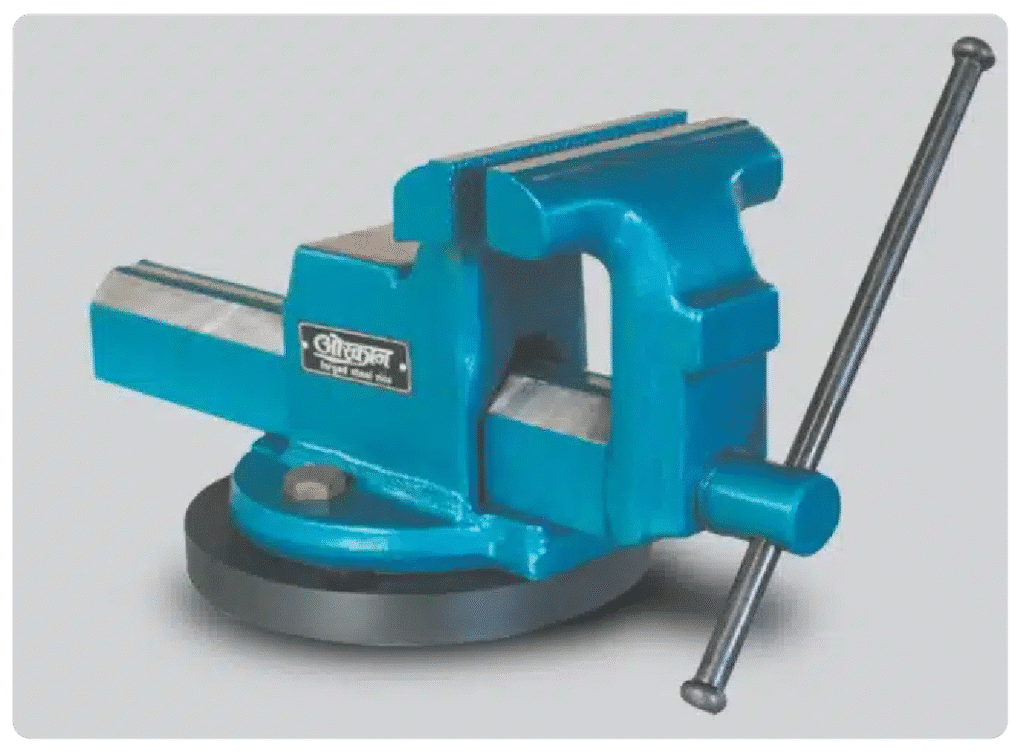

Vices and

Machine Vices

“High-precision bench and machine vices, manufactured

in India for tough, everyday industrial use.”

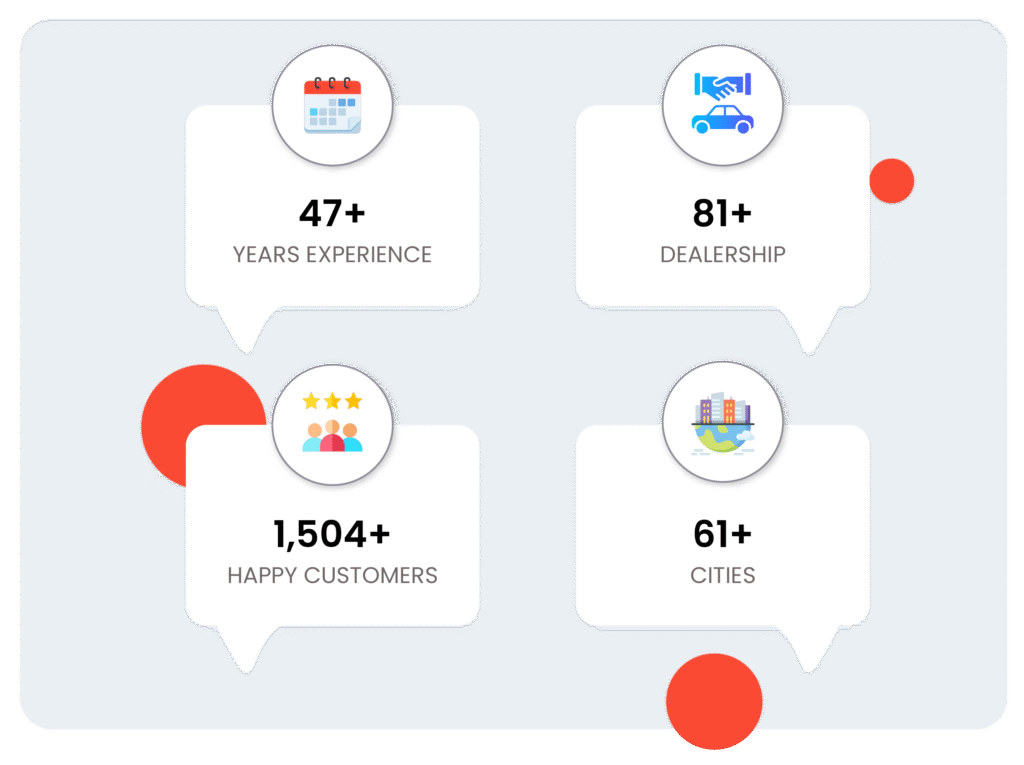

47

YEARS OF VICE

MANUFACTURING

Vices and

Machine Vices

“High-precision bench and machine vices, manufactured

in India for tough, everyday industrial use.”

47

YEARS OF VICE

MANUFACTURING

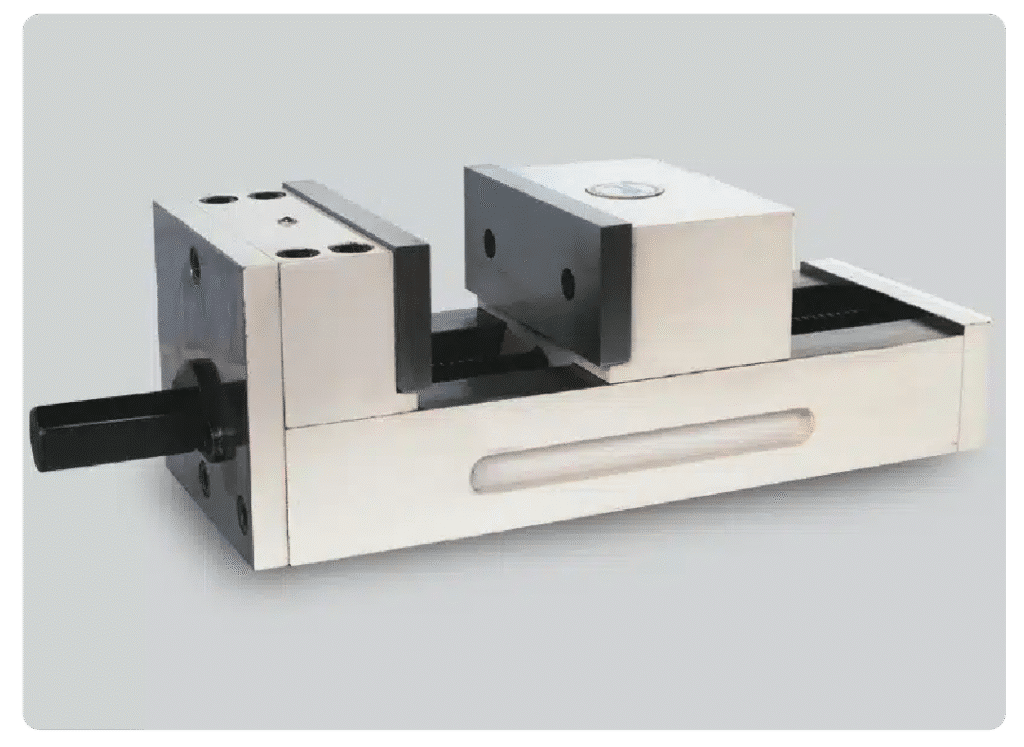

When making a purchase investment in work-holding vices, at Orcan, we focus on delivering Durable rear jaw sliding bench vices. Steel-forged bench vices are a popular choice in many European countries. Orcan Machine Vices meets client demands in terms of productivity, performance & precision. We also customise vices to meet specific job and machine suitability

Innovative Products

SAVING TIME AND MONEY

Client Verticles

Engineering Colleges

Engineering colleges buy vices to train students how to use vices in a mechanical workshop. Many renowned colleges use orcan vices.

CNC Cutting Tools

Machine vices for VMC, grinding vices can be sold to the common clients of cutting tools, Dealers who sell consumables for VMC

Garage Tools

Automotive garages for bikes and cars typically include a bench vice in their garage tool list. Many of Dealers sell in them

Hand Tools

Hand tools designed for strength, precision, and reliability, ensuring faster work, higher safety, and superior performance every time.

Machine Tools

Machine tools is a segment of the manufacturing industry where several pieces of equipment for shaping and assembly are used.

Bearing Puller

Bearing replacement in portable tools like drills and marble cutters risks armature damage, raises safety concerns, and is slow manually

Durable and Innovative Bench Vices & Machine Vices

A dovetail machine vice, has a special construction with the body having a dovetail guide & moving jaw also has dovetail slide .Bene t of this special construction is the jaw lift on tighening the workpiece is with in 20 microns

Discover Orcan’s drop forged bench vices, meticulously developed at the request of a prestigious European client and now a top choice across Europe

Portable power tools, such as marble cutters, have less

space between the bearing and armature windings.

Any damage to the winding means an increase in

repair costs and wastage of time

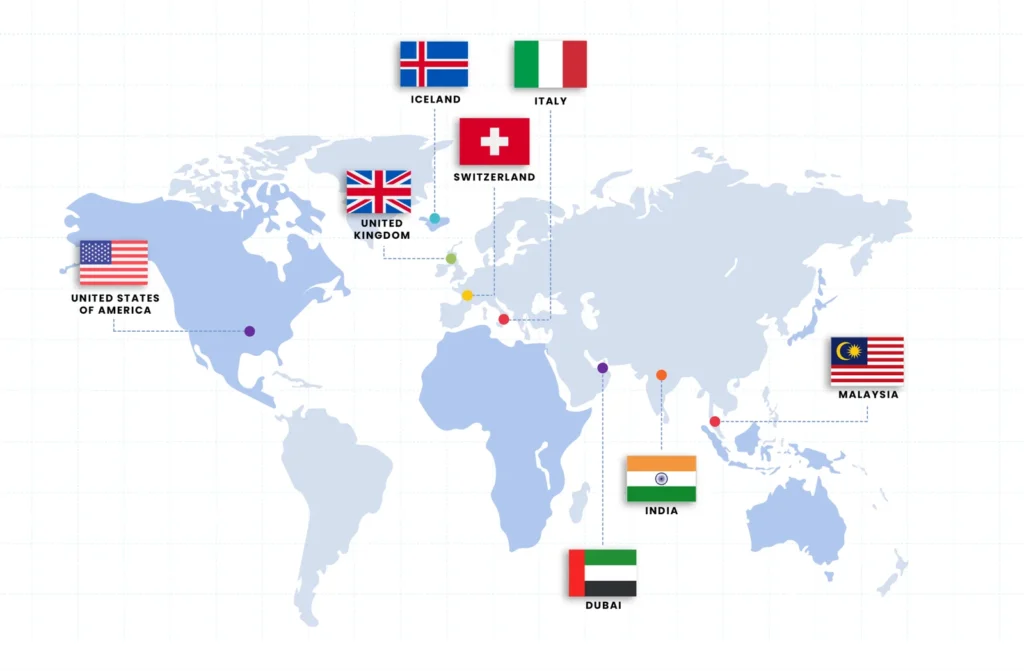

Countries Trusting Orcan Vinces

For decades, Orcan vices have been the choice of manufacturers and engineers in India and across the globe—including Switzerland, Italy, Malaysia, the UK, Iceland, the USA, and Dubai—valued for their precision, durability, and consistent performance.

Countries Trusting Orcan Vinces

For decades, Orcan vices have been the choice of manufacturers and engineers in India and across the globe—including Switzerland, Italy, Malaysia, the UK, Iceland, the USA, and Dubai—valued for their precision, durability, and consistent performance.

Exhibitions attended