workholding tools

World of Vice Industry

World of Vice Industry

Delivering Durability, Precision & innovation in vice for the bench and machines

- Warranty of 10 years on the breakage of the Nut for the bench vise.

- Twin job clamping machine vice for enhanced productivity.

- Pneumatic machine vise for the fatigue-free, consistent clamping

46 Years of Experience in Manufacturing Vices.

When it comes to workpiece clamping, the range of products is extensive, starting from bench vices to hold manual operating workpieces to machine vices that clamp workpieces. At the same time, metal cutting is done on CNC machines, such as vertical machining centers, milling machines, drill machines, or Horizontal machining Centers.

We offer a wide range of vices, covering jaw widths from 2″ to 10″, with varied jaw openings and a variety of material constructions.

■ OUR MISSION

To Manufacture innovative Vises keeping customer applications ,Durability & Precision at core of Engineering values

■ OUR VISION

Achieve leadership statuts in professional hand tools business in india by best in class products and services

CLIENT VERTICLES

Orcan Vices are in use in Automotive Garrages ,Manufacturing Plants,Engineering colleges ,CNC machines .

OEM

(OEMs) Producing vehicle lifts for two-wheelers and four-wheelers, a vice can be an essential tool used during the manufacturing and assembly process

Suppliers to college

Using technical training facilities where students learn practical skills related to engineering, mechanics, woodworking, metalworking, and more

CNC Cutting tools

Machine vices for VMC, grinding vices can be sold to the common clients of cutting tools

Machine tools

In the context of machine tool dealers, a “vice” refers to a mechanical tool used to hold and secure workpieces during machining, fabrication, or other processes.

Garage tools

Automotive garages for bikes and cars typically include a bench vice in their garage tool list.

VICES CATEGORIES CLASSIFIED AS PER USAGE AND MATERIALS

Another practical way to categorize vices is based on their mode of use, whether it’s manual or automated. This knowledge will help you with the necessary information to do your tasks effectively.

Our range of vices is broadly categorized into two main types, workbench vices and machine-mounted vices. This precise classification will help you focus on the specific type you need for your work.

Heavy Duty Bench Vice

An industrial bench vice, often referred to as a “vice,” is a workholding tool commonly used in manufacturing workshops, automotive garages, Vocational training colleges, and other similar settings.

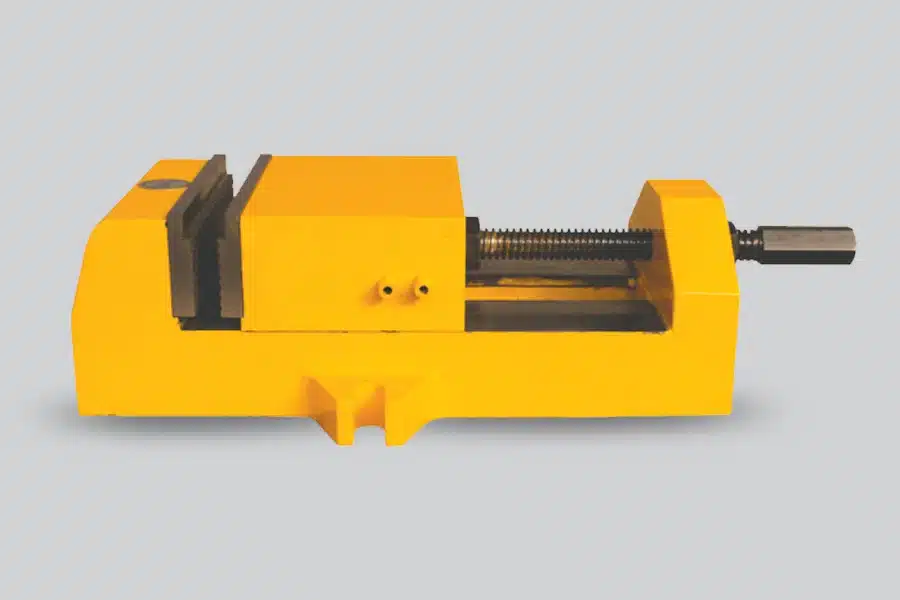

Machine Vice

A machine vice is a mechanical Device designed & Engineered to securely clamp the workpiece in place during machining on a milling machine or vertical machining center, as well as during fabrication.

COUNTIRES TRUSTING ORCAN VICES

Our range of heavy-duty bench vices is also being used regularly by OEM clients.

FAQs

Why & where of vices (vices)

Bench Vice

Bench Vices are designed for use on a workbench. The vice is mounted on the table or workbench, and operators use it to clamp the workpiece, such as when filing, cutting, or sizing.

What is bench vice price

Bench vice price is based on specifications like bench vice material, casted/forged, size of bench vice 4/5/6/8″ jaw width, and parts of bench vice, like swivel base, pipe clamp jaws. It’s also based on the type of bench vices, like manual or automatic.

Milling Machine Vice

Milling vices, also known as machinist vices, are mounted on machines such as milling machines, Vertical machining Centers, or drilling machines to clamp the workpiece. In contrast, it’s machined using metal-cutting tools like face mills, end mills, or shoulder mills.

The jaw width and jaw opening are two of the primary parameters upon which the vice is selected; other parameters are the materials of construction, the jaw geometry, etc.

The durability of the manual machine vice is also dependent on the diameter of the Screw and the thread type

Twin part clamping vmc machine Vice

These vices are specially designed to improve the productivity of vertical machining centers or horizontal machining centers.

Using multiple vices on the machine table can substantially improve productivity. The tool change time is divided by twice the number of vices. With four vices being used on the machine bed, the tool change time of 30 seconds is divided by 8.

Self Centering machine vice

Self-centering vices are used on milling machines to machine features like keyways, where the job size might change, but the center of the job should remain the same to allow for fast job change.

Orcan’s self-centering vices, available in various sizes from 2″ to 5″ and with jaw openings from 2″ to 6″, are designed to enhance efficiency and save time in the machining process.

what is a Grinding Vice

Surface grinding vices are used on surface grinding machines. They are also referred to as toolmakers’ grinding vices. Grinding vice sizes vary from 50mm to 100mm jaw width and opening 150mm.

Pneumatic Vice Benefits

In this type of vice, the clamping pressure is applied to the workpiece using an internal cylinder with compressed air at 7.5 bar.

Pneumatic vices deliver a consistent clamping force that does not change throughout the day due to operator fatigue.

Additionally, the clamping & unclamping operations are high-speed, saving valuable time for both the operator & machine, thereby increasing the productivity of both.

It’s also very beneficial to use them in assembly operations. It can also be used with a Foot switch to free the hands.

Swivel base

The swivel base is an optional accessory that can be used with bench vices or machine vices. . .it allows users to rotate the vice in the XY plane at an angle and work on the workpiece

Warranty

Rear Jaw sliding bench vices in the heavy duty range that are sizes 5″,6″ & 8″ come with 3 3-year warranty against breakage, and they come with 10 10-year warranty against breakage of the NUT.

Machine vices come with a one-year warranty against manufacturing defects only.

Material of vice construction

Vices can be manufactured in Cast iron Casting, SG iron casting, Steel casting, or steel, alloy steel, or drop forged steel vice